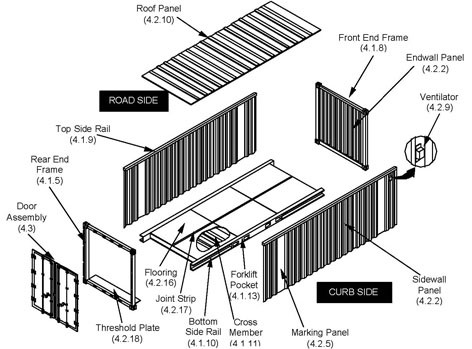

A client's cargo is packed and ready. You've booked a 40ft container. The numbers check out—the crate is six inches narrower than the container's internal width. But when the truck arrives for loading, the crate won't fit. It's a fraction of an inch too wide for the door opening. Now you're dealing with a failed loading, a delayed shipment, and an unhappy client, all because of a detail buried in the spec sheet.

Beyond the Numbers: The Three Dimensions That Matter

External Dimensions: For the Carrier, Not Your Cargo

The standard external width is 8 feet (2.44m). These dimensions are critical for shipping lines, port operators, and trucking companies because they dictate how containers are stacked on vessels, stored in yards, and transported on chassis. For your cargo planning, however, these numbers are largely irrelevant.

Internal Dimensions: Your Actual Loading Space

This is your loadable area. The internal width of a standard container is typically around 7 feet 8 inches (2.35m). The difference is due to the thickness of the container walls and the corrugated steel structure. Always use the internal dimensions to calculate if your cargo will fit, and remember that slight variations exist between manufacturers.

Door Opening: The Overlooked Bottleneck

This small difference can mean the success or failure of loading oversized or tightly packed cargo.

For any non-standard or bulky cargo, always confirm the minimum door opening dimensions, not just the internal specs.

20ft vs. 40ft Containers: It's About Density, Not Just Size

20ft Dry Container: Best for heavy, dense cargo

Think machinery, steel, bagged agricultural products, or raw materials. With a 20ft container, you will almost always reach the maximum payload weight long before you run out of physical space. It's built for weight, not volume.

40ft Dry Container (and High Cubes): Best for voluminous, lighter cargo

This includes furniture, electronics, apparel, and plastic goods. With a 40ft container, you are more likely to fill the entire cubic space before hitting the weight limit. It's built for volume.

Using the wrong container type is a common way to overspend. Putting light, bulky goods in two 20ft containers instead of one 40ft container can nearly double your ocean freight cost for no reason.

Understanding Container Weights: Tare, Payload, and Gross

- Tare Weight: The weight of the empty container. A 20ft container weighs around 5,000 lbs (2,270 kg).

- Payload: The maximum weight of cargo the container is certified to hold. For a 20ft, this is typically around 61,000 lbs (27,600 kg).

- Gross Weight: Tare + Payload = the maximum combined weight.

Container Identification Codes

The series of letters and numbers on a container door provides its unique identity. For example, in GFLU 123456 7 45G1:

- Owner code (4 letters)

- Serial number (6 digits)

- Check digit (1 digit)

- Size/type code (4 characters)

When Standard Won't Work: Specialized Containers

- Open Top Containers: Have a removable tarpaulin roof, allowing oversized cargo to be loaded from the top.

- Flat Rack Containers: Have collapsible sides to accommodate oversized, wide, or heavy cargo.

- Tank Containers: A tank within a standard 20ft frame, for bulk liquids, gases, or powders.

Maximizing Space: A Practical Guide to Pallet Loading

- 20ft container: Can typically fit 11 Standard pallets or 10 Euro pallets.

- 40ft container: Can typically fit 22 Standard pallets or 24 Euro pallets.